При работе с тяжелыми грузами, такелажные стропы — жизненно важные инструменты. Их используют при подъеме, обеспечение, и перемещение тяжелого оборудования. Но как долго можно ожидать, что такелажный строп прослужит?? Понимание ожидаемого срока службы такелажа имеет важное значение для безопасности., эффективность, и экономичность в промышленных условиях.

Что такое Такелажный строп?

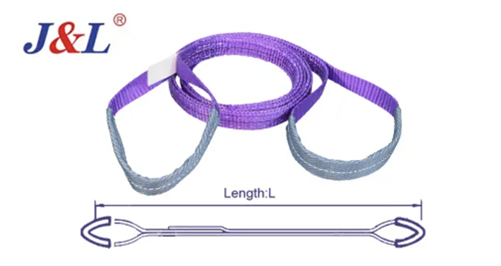

Такелажные стропы – это грузоподъемные устройства, используемые в различных отраслях промышленности., в том числе строительство, производство, и доставка. Эти стропы изготовлены из таких материалов, как нейлон., полиэстер, трос, или цепь. Они предназначены для безопасного подъема и перемещения тяжелых предметов.. Такелажные стропы выпускаются в нескольких видах., например, плоские стропы, круглые стропы, и цепные стропы. Каждый тип подходит для различных подъемных применений..

Факторы, влияющие на срок службы такелажных строп

На срок службы такелажного стропа влияют несколько факторов.. К ним относятся:

- Тип материала: Материал стропы играет значительную роль в ее сроке службы.. Стропы из полиэстера и нейлона, например, имеют различную прочность по сравнению со стальными цепями или проволочными канатами.

- Частота использования: Стропы, которые используются часто или для тяжелых грузов, имеют тенденцию изнашиваться быстрее..

- Условия окружающей среды: Воздействие суровых условий, таких как экстремальные температуры., химикаты, и УФ-излучение может испортить материал стропа..

- Размер загрузки: Перегрузка строп или неправильное их использование могут значительно сократить срок их службы..

- Обслуживание: Правильный уход, инспекция, и хранение могут значительно продлить срок службы вашего такелажа.

Как долго служат такелажные стропы?

Срок службы такелажного стропа может варьироваться в зависимости от типа и условий использования.. Обычно, стропы регулярно проверяются, и их замена планируется на основании визуального осмотра и рекомендаций производителя.. В общем, продолжительность жизни может варьироваться от 2 к 10 годы, в зависимости от нескольких факторов.

Срок службы в зависимости от типа материала

- Нейлоновые стропы: Обычно последний 2-5 годы.

- Полиэстеровые стропы: Обычно длится 3-6 годы.

- Стальные цепные стропы: Может длиться 10-20 годы.

- Проволочные канатные стропы: Иметь продолжительность жизни около 5-15 годы.

Срок службы такелажных строп в зависимости от материала

| Тип материала | Средняя продолжительность жизни | Общие приложения | Советы по обслуживанию |

|---|---|---|---|

| Нейлон | 2-5 годы | Подъем легких и средних нагрузок | Регулярный осмотр на наличие порезов и потертостей. |

| Полиэстер | 3-6 годы | Тяжелый подъем, устойчивый к ультрафиолетовому излучению | Избегайте длительного пребывания на солнце |

| Стальная цепь | 10-20 годы | Тяжелый промышленный подъем | Регулярно проверяйте на наличие коррозии |

| Проволочный канат | 5-15 годы | Оснащение для суровых условий | Содержать в чистоте и смазать |

Признаки того, что такелажный строп необходимо заменить

Знание того, когда следует заменить такелажный строп, имеет решающее значение для безопасности.. Некоторые общие признаки включают:

- Видимые порезы или разрывы: Это главный предупреждающий знак. Любое видимое повреждение стропы может поставить под угрозу ее прочность и безопасность..

- Потертые или изношенные участки: Если вы заметили потертости или потертости, особенно вблизи несущих зон, пришло время замены.

- Обесцвечивание: Длительное воздействие ультрафиолетовых лучей может ослабить стропы.. Если слинг потускнел или изменил цвет, it’s time to check its integrity.

- Stretching or Elongation: Overloaded slings may stretch beyond their normal limits, which weakens the sling.

Signs of Damage and When to Replace Your Rigging Sling

| Type of Damage | Описание | Action Required | Replacement Timeline |

|---|---|---|---|

| Cuts or Tears | Any cuts or tears in the sling material. | Immediate replacement required. | Immediate |

| Fraying | Visible fraying or wear on the fabric. | Inspect for internal damage. | 6 months to 1 year |

| Обесцвечивание | Fading or color changes due to UV exposure. | Inspect closely for weakening. | 1-2 годы |

| Stretching | The sling has visibly elongated. | Check load capacity. | 1 year (frequent use) |

How to Maximize the Life of Your Такелажный строп?

To ensure your rigging sling lasts as long as possible, follow these tips:

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for usage and maintenance.

- Inspect Regularly: Проводите частые визуальные проверки. Ищите любые признаки износа или повреждения.

- Избегайте перегрузки: Не превышайте номинальную грузоподъемность стропа..

- Правильное хранение: Храните стропы в сухом, чистая окружающая среда, вдали от сильной жары, холодный, и прямые солнечные лучи.

- Используйте защитное оборудование: При подъеме грузов с острыми краями или неровными краями, используйте защитные рукава или прокладку, чтобы предотвратить повреждение стропа.

Понимание подъемных строп и. Такелажные стропы

При этом подъемные и такелажные стропы аналогичны., они служат немного другим целям. Подъемные стропы обычно используются для подъема предметов, пока такелажные стропы являются частью всей такелажной системы и могут использоваться для подъема грузов., обеспечение, или размещение тяжелых грузов. Оба типа строп играют важную роль при подъеме тяжелых грузов..

Сравнение Подъемные стропы и такелажные стропы

| Особенность | Подъемные стропы | Такелажные стропы |

|---|---|---|

| Основное использование | Подъемные объекты | Подъем, обеспечение, позиционирование нагрузок |

| Варианты материалов | Нейлон, полиэстер, трос | Цепь, трос, полиэстер, нейлон |

| Соображения безопасности | Грузоподъемность, износ | Проверка точек нагрузки и соединений |

| Продолжительность жизни | 2-5 годы (Нейлон) | 5-20 годы (Стальные цепи) |

Заключение

Срок службы такелажного стропа зависит от различных факторов, таких как материал, использование, среда, и обслуживание. Соблюдая правила техники безопасности и обеспечивая регулярные проверки, вы можете продлить срок службы такелажа. Помнить, безопасность превыше всего, а использование хорошо обслуживаемого оборудования снизит риск несчастных случаев и повысит производительность в промышленных условиях..

Регулярно заменяйте такелажные стропы, имеющие признаки износа., и всегда следуйте инструкциям производителя по правильному уходу и использованию.. С правильными мерами предосторожности, ваш такелажный строп может прослужить долгие годы, обеспечение безопасного и эффективного подъема.