Excavator hydraulic pumps are devices that are used to generate the hydraulic power required to operate excavator equipment. Hydraulic pumps are responsible for the movement of the machine’s estrondo, braço, e balde, and they provide the power to drive the tracks or wheels of the excavator.

Hydraulic pumps work by converting mechanical energy from the engine or motor of the excavator into hydraulic pressure. This pressure is then used to move hydraulic fluid through the system, which in turn powers the excavator’s hydraulic motors and cylinders.

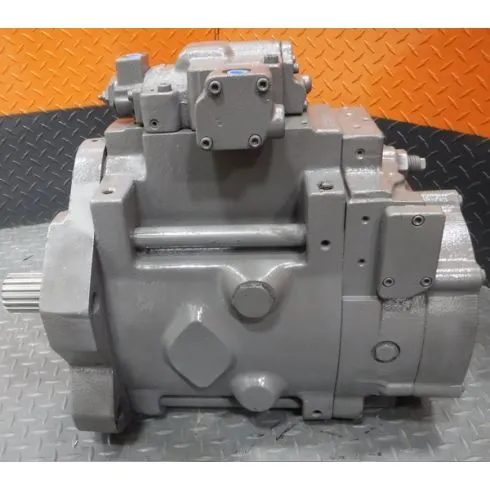

There are several types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps. Each type of pump has its own unique advantages and disadvantages in terms of efficiency, power output, and cost.

Understanding the Importance of Excavator Hydraulic Pumps

Excavator hydraulic pumps are an essential component of any construction site, providing the hydraulic pressure required to power the various components of the excavator machine. These pumps are responsible for powering the boom, braço, and bucket of the excavator, as well as the tracks or wheels that allow it to move around the site.

Without a functioning hydraulic pump, an excavator would be unable to perform its primary functions, which include digging, escavando, and lifting heavy loads. This makes it critical for construction companies to understand the importance of excavator hydraulic pumps and ensure that they are properly maintained.

One of the primary benefits of using hydraulic pumps in excavators is their ability to generate high amounts of power with relatively low energy consumption. This makes them an efficient and cost-effective solution for powering heavy-duty equipment. Adicionalmente, hydraulic pumps can be easily controlled, allowing operators to adjust the speed and direction of the excavator with precision.

There are several types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps. Each type of pump has its own unique advantages and disadvantages, depending on factors such as efficiency, power output, and cost.

To ensure that hydraulic pumps are functioning correctly, regular maintenance and inspections are necessary. Isso inclui a verificação de vazamentos, inspecting the pump for wear and tear, and replacing any damaged or worn parts.

Which Brands Of Excavator Hydraulic Pumps Do We Carry?

Principais fabricantes de cilindros hidráulicos

FUJIAN TONGZHOU MACHINERY CO.,LTD. está localizado na cidade de Quanzhou,Província de Fujian. É uma empresa de produtos hidráulicos de máquinas de engenharia modernizada integrada com R&D, fabricação e vendas.

A empresa possui linha de produção de cilindros de óleo hidráulico e 30 mais outros equipamentos recém-adicionados ,entre os quais 95% ou mais são máquinas CNC. Tem muitos tipos de linhas horizontais de refino térmico de média frequência e linhas horizontais de endurecimento de superfície de média frequência,máquinas de esqui importadas,fresadoras de furos profundos,esmerilhadeiras externas de alta precisão,Máquinas de solda automática CNC,máquinas de solda por fricção importadas,máquina de limpeza automática,linhas de galvanoplastia automática para níquel&cromo,auto assembly lines and auto printing line etc…

Tem capacidade especial de fabricação e processamento para todos os tipos de cilindros de óleo.