Excavator hydraulic pumps are devices that are used to generate the hydraulic power required to operate excavator equipment. Hydraulic pumps are responsible for the movement of the machine’s бум, рука, и ведро, and they provide the power to drive the tracks or wheels of the excavator.

Hydraulic pumps work by converting mechanical energy from the engine or motor of the excavator into hydraulic pressure. This pressure is then used to move hydraulic fluid through the system, which in turn powers the excavator’s hydraulic motors and cylinders.

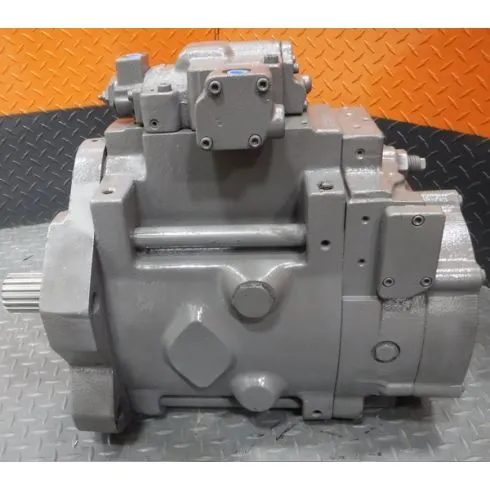

There are several types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps. Each type of pump has its own unique advantages and disadvantages in terms of efficiency, power output, and cost.

Understanding the Importance of Excavator Hydraulic Pumps

Excavator hydraulic pumps are an essential component of any construction site, providing the hydraulic pressure required to power the various components of the excavator machine. These pumps are responsible for powering the boom, рука, and bucket of the excavator, as well as the tracks or wheels that allow it to move around the site.

Without a functioning hydraulic pump, an excavator would be unable to perform its primary functions, which include digging, раскопки, and lifting heavy loads. This makes it critical for construction companies to understand the importance of excavator hydraulic pumps and ensure that they are properly maintained.

One of the primary benefits of using hydraulic pumps in excavators is their ability to generate high amounts of power with relatively low energy consumption. This makes them an efficient and cost-effective solution for powering heavy-duty equipment. Кроме того, hydraulic pumps can be easily controlled, allowing operators to adjust the speed and direction of the excavator with precision.

There are several types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps. Each type of pump has its own unique advantages and disadvantages, depending on factors such as efficiency, power output, and cost.

To ensure that hydraulic pumps are functioning correctly, regular maintenance and inspections are necessary. This includes checking for leaks, inspecting the pump for wear and tear, and replacing any damaged or worn parts.

Which Brands Of Excavator Hydraulic Pumps Do We Carry?

Лучшие производители гидроцилиндров

FUJIAN TONGZHOU MACHINERY CO., LTD.. расположен в городе Цюаньчжоу,Провинция Фуцзянь. Это модернизированная компания по производству гидравлических машин, интегрированная с R.&Д, производство и продажа.

Компания имеет линию по производству гидравлических масляных цилиндров и 30 больше другого недавно добавленного оборудования ,среди которых 95% или более станки с ЧПУ. Он имеет много типов горизонтальных среднечастотных линий термического рафинирования и горизонтальных среднечастотных линий поверхностной закалки.,импортные шлифовальные машины,станки для фрезерования глубоких отверстий,высокоточные наружные шлифовальные станки,Автоматические сварочные аппараты с ЧПУ,импортные автоматические сварочные аппараты трением,автоматическая машина для очистки,автоматические гальванические линии для никеля&хром,auto assembly lines and auto printing line etc…

Он имеет специальные производственные и технологические возможности для всех видов масляных цилиндров..