Excavator hydraulic pumps are devices that are used to generate the hydraulic power required to operate excavator equipment. Hydraulic pumps are responsible for the movement of the machine’s boom, arm, and bucket, and they provide the power to drive the tracks or wheels of the excavator.

Hydraulic pumps work by converting mechanical energy from the engine or motor of the excavator into hydraulic pressure. This pressure is then used to move hydraulic fluid through the system, which in turn powers the excavator’s hydraulic motors and cylinders.

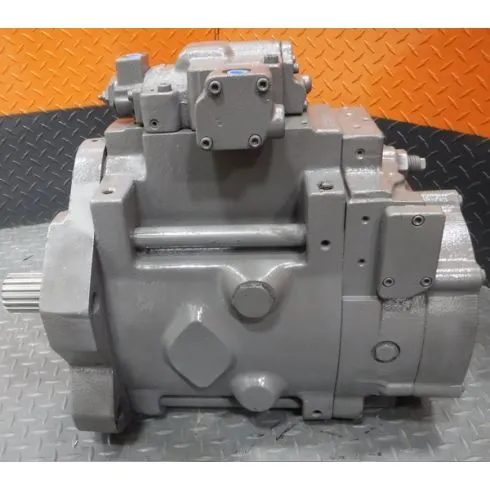

There are several types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps. Each type of pump has its own unique advantages and disadvantages in terms of efficiency, power output, and cost.

Understanding the Importance of Excavator Hydraulic Pumps

Excavator hydraulic pumps are an essential component of any construction site, providing the hydraulic pressure required to power the various components of the excavator machine. These pumps are responsible for powering the boom, arm, and bucket of the excavator, as well as the tracks or wheels that allow it to move around the site.

Without a functioning hydraulic pump, an excavator would be unable to perform its primary functions, which include digging, excavating, and lifting heavy loads. This makes it critical for construction companies to understand the importance of excavator hydraulic pumps and ensure that they are properly maintained.

One of the primary benefits of using hydraulic pumps in excavators is their ability to generate high amounts of power with relatively low energy consumption. This makes them an efficient and cost-effective solution for powering heavy-duty equipment. Additionally, hydraulic pumps can be easily controlled, allowing operators to adjust the speed and direction of the excavator with precision.

There are several types of hydraulic pumps used in excavators, including gear pumps, vane pumps, and piston pumps. Each type of pump has its own unique advantages and disadvantages, depending on factors such as efficiency, power output, and cost.

To ensure that hydraulic pumps are functioning correctly, regular maintenance and inspections are necessary. This includes checking for leaks, inspecting the pump for wear and tear, and replacing any damaged or worn parts.

Which Brands Of Excavator Hydraulic Pumps Do We Carry?

Top hydraulic cylinder manufacturers

FUJIAN TONGZHOU MACHINERY CO.,LTD. is located in Quanzhou city,Fujian Province. It is a modernized engineering machine hydraulic product company integrated with R&D, manufacturing and sales.

The company has hydraulic oil cylinder production line and 30 more other newly-added equipments ,among which 95% or more are CNC machines. It has many types of horizontal mid-frequency thermal refining lines and horizontal mid-frequency surface hardening lines,imported skiving machines,deep hole milling machines,high precision external grinders,CNC auto welding machines,imported auto friction welding machines,auto cleaning machine,auto electroplating lines for Nickel&chromium,auto assembly lines and auto printing line etc…

It has special manufacturing and processing capability for all kinds of oil cylinders.